What is hydrogen and how is it obtained?

Under normal conditions, hydrogen is gaseous, tasteless, odourless, and colourless. It is also the most abundant chemical element on the planet, is light, can be stored and does not generate pollutant emissions of its own. With these characteristics in mind, it is the perfect candidate for a fuel. However, it cannot be extracted directly from nature as it is combined with other elements and needs to be processed.

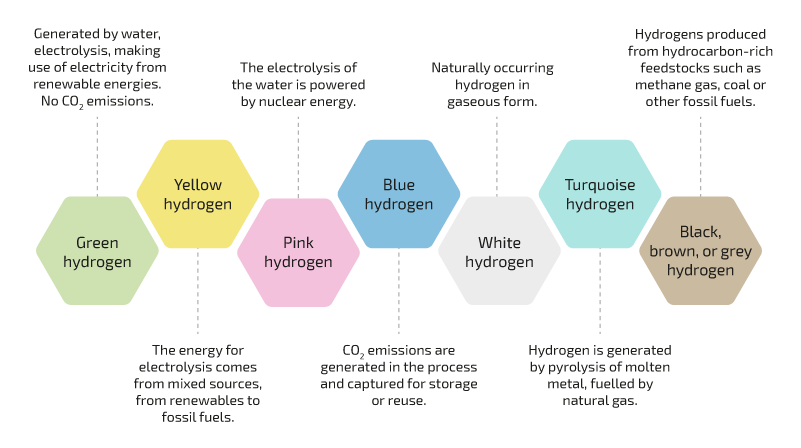

It is according to the type of energy used in the production process and its origin, whether it is renewable or not, that determines its colour. Thus, we can find green, yellow, pink, blue, white, turquoise, black-grey and brown hydrogen.

The Colors of Hydrogen

At present, most hydrogen is generated from fossil fuels, as it is the cheapest to produce but the process does give off a large amount of CO2 into the atmosphere. For hydrogen to fulfil its crucial role as a decarbonisation tool, a significant expansion of clean hydrogen will be needed. This can be produced through renewable energy or fossil fuels combined with emission reduction measures such as carbon capture and storage.

What is green hydrogen or sustainable hydrogen?

Green hydrogen is obtained from a water electrolysis process driven by renewable energies such as solar or wind power. In other words, green hydrogen is hydrogen that has been obtained without generating polluting emissions, which makes it a clean, sustainable hydrogen with a zero-pollution index.

Hydrogen is a key energy carrier for achieving the decarbonisation of the planet and meeting the commitments set for 2050 in the fight against climate change as it plays a key role in the reduction of greenhouse gases.

It is estimated that demand for clean hydrogen could grow to approximately 660 million metric tonnes per year by 2050.

But the development of hydrogen production projects is just as important such as investing in pipeline and transport infrastructure like the H2Med corridor. It is the first major hydrogen corridor in the European Union which will connect Portugal and Spain with France and Germany.

Clean Hydrogen Applications

As mentioned above, in the process of generating clean hydrogen, no CO₂ is emitted, making it a decisive solution for decarbonising sectors where it is very difficult to reduce emissions, as long as it is complemented by other technologies such as renewable energies and biofuels.

CLEAN HYDROGEN CAN CONTRIBUTE TO THE REDUCTION OF 80 GIGATONNES OF CO2 BY 2050.

Examples of sectors

Industry: for the manufacture of steel or the synthesis of ammonia to produce fertilisers.

Land mobility: as a fuel for heavy trucks or passenger cars.

Maritime transport and aviation: to produce synthetic fuels for ships.

Heating: as high-grade industrial heat.

Power generation: either as supply energy or as a back-up power source

Industry and transport represent the sectors with the largest share of emission reduction potential thanks to hydrogen, whose cumulative reduction is estimated at 80 gigatonnes of CO2 until 2050.

HYDROGEN AND THE TRANSPORT INDUSTRY

Given the potential benefits and expected growth of hydrogen, the transport industry is preparing for a hydrogen-powered future.

As stated by the consulting firm McKinsey, although passenger cars will also contribute to hydrogen consumption, about 95% of the demand by volume will come from commercial vehicles. Japan and South Korea are the exception to this, where hydrogen for passenger cars is receiving strong support and domestic OEMs are leading the development of fuel cell electric vehicles (FCEVs).

Compared to battery energy storage, hydrogen-powered lorries can refuel faster and have a longer range, as well as having a lower weight penalty due to the fact that the tanks weigh considerably less than batteries.

Hydrogen lorries can be deployed on a similar scale to diesel lorries, but with the advantage of producing zero emission. By 2030, the TCO (Total Cost of Ownership) to operate a lorry travelling 500 km/day in Europe is estimated to reach €1.13 per kilometre for diesel, €1.03 for battery electric lorries and €1.02 for fuel cell lorries.

The technology required for these lorries and for generating hydrogen has already been developed and implemented. In contrast, the hydrogen infrastructure such as refuelling stations and a value chain for supply is seen as the main bottleneck for this transition.

Green Steel and Hydrogen

In the steel industry, hydrogen could be used as an energy source for reaching the temperatures required in the steel production process, as well as a reducing agent for generating alloys, displacing the use of coal.

In order to make this transition, large upfront investments have to be made. But hydrogen steelmaking has the potential to massively reduce the industry’s footprint: steel is expected to generate around 8% of clean hydrogen demand by 2030 and could account for almost 20% of the emissions avoided through hydrogen that year.

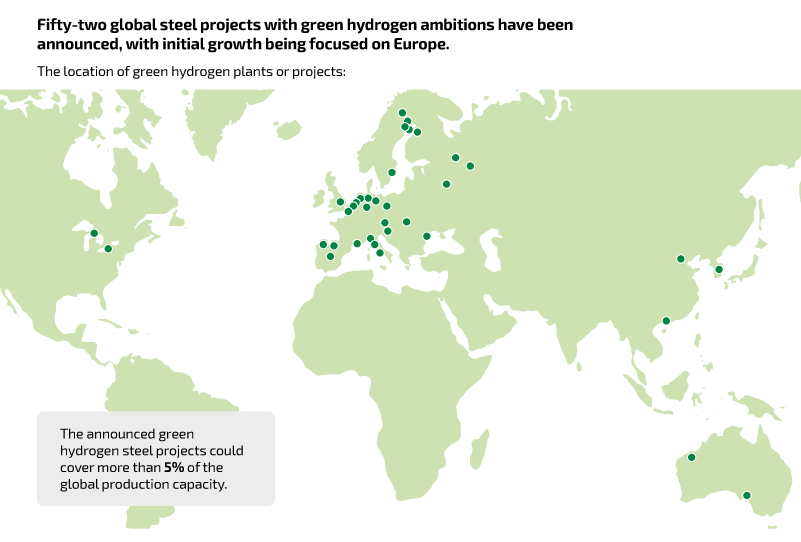

More than 50 steel projects with green hydrogen ambitions have been announced worldwide, positioning Europe as an early growth powerhouse.

Aratubo and the Arania Group share the core objective of using steel with zero CO2 emissions.

Through the Arania Group’s agreement with the Salzgitter Group, we are able to ensure the delivery of zero-emission steel from the end of 2025 onwards and maintain the production of high-quality steel, confirming our commitment to sustainability and the fight against climate change.

Green hydrogen for the energy transition

By 2050, clean hydrogen, as a scalable and cost-effective energy carrier, could facilitate the reduction of seven gigatonnes of CO2 emissions per year, which is the equivalent to 20% of mankind’s emissions if the current global warming trajectory is maintained. This is why its momentum is vital to achieving the climate goals of the Paris Agreement and the zero emissions targets required by the climate emergency.

To meet the goal of limiting global warming to 1.5 – 1.8 degrees Celsius by 2050, the world needs more than 660 million tonnes of hydrogen. This is in addition to balancing the gap between places where hydrogen is in high demand but low supply, such as Japan, and where there is low demand but high supply, such as Namibia or Chile.

It will therefore be crucial for different stakeholders to take action over the next decade to make hydrogen development a reality. Future action on the following will be vital in order to unlock the transition to hydrogen:

the drive of demand for clean hydrogen from different sectors

the development of infrastructures to enable end-user access to hydrogen

and improving cost competitiveness by accelerating the scale-up of clean hydrogen deployment.